Reliable wastewater disposal is crucial in plumbing. In this article, we will take a closer look at the role of ventilation and venting in wastewater systems according to the Austrian standard ÖNORM. Learn how targeted balancing of negative and positive pressure helps minimize unwanted side effects such as unpleasant odors and health risks, and discover how products like pipe aerators contribute to this.

“Seestadt Aspern” in the north-east of Vienna is currently the largest housing and urban development project in Europe and is set to provide living space for over 25,000 people by 2030. That means it has more inhabitants than some small towns. Creating living space for so many people in such a small area brings with it many structural challenges. Drinking water supply and, above all, wastewater disposal also play a major role here. The average european uses around 130 litres of fresh water per day within their household. Taking the “Seestadt Aspern” as an example, this means that around 3 million liters of wastewater have to be disposed of every day. A sophisticated drainage system is required to ensure that this amount of water can drain away properly and without unpleasant side effects. Common problems caused by poor planning or installation of drainage pipes include smell development, noise (e.g. gurgling in the sink) or inadequate drainage performance and the associated consequential damage. In extreme cases, a poor sewage pipe system can even pose a health risk, e.g. if toxic foul gases enter the living space.

Sewage pipe ventilation (pipe aeration for underpressure and pipe de-aeration for overpressure) is important for the proper installation of drainage pipes. Regardless of whether it is a detached house or a residential complex – correct ventilation for wastewater pipes is an absolute necessity in order to dispose of water effectively and properly.

Difference of aeration and deaeration

Ventilation is carried out via ventilation pipes which, as a connection between the waste water pipe and the atmosphere, ensure the necessary pressure balancing. Pipe ventilation is often not differentiated precisely enough. Pipe aeration and pipe deaeration are often both called “ventilation”, which is true but the airing and the de-airing of a system are two different topics that cause different problems.

Overpressure

Ventilation of overpressure involves eliminating excess pressure in the pipe system or venting this excess pressure. Overpressure in the pipework system is caused on the one hand by foul gases in the sewerage system. On the other hand, it is also caused by pipe deflections in which the flow in the deflection area is converted from velocity energy into pressure energy, resulting in additional air compression which tends to escape upwards. High overpressure in the pipe system leads to undesirable phenomena in the drainage systems. The overpressure can be so strong that the water is prevented from draining (the overpressure in the system acts as an air cushion that prevents the water from draining), that there are disturbing noises (‘gurgling’ in sinks, for example) or that foul gas enters the living space (overpressure ‘pushes’ gas through the water barrier of the trap). The problems caused by a lack of/incorrect ventilation are therefore manifold and range from water damage due to a lack of drainage capacity to unpleasant odours and in extreme cases damage to health caused by foul gases.

Underpressure

Waste water pipe ventilation is about preventing negative pressure / underpressure in the pipe system. Imagine you want to empty a full bottle with a small opening quickly. As soon as you turn the bottle over, it will empty slowly and unevenly with gurgling noises. If you pierce or drill a ventilation hole in the base of the bottle, you will notice that the bottle empties much faster and more evenly. The reason for this is that air can be drawn in through the ventilation hole in the base of the bottle, which is necessary to prevent the negative pressure that is responsible for gurgling. In sewage systems within a house, underpressure caused by sewage falling down the downpipe should also be prevented. Excessive negative pressure in the system causes the traps in the drainage systems of the house to be sucked dry. The consequence of this is unpleasant odours or even damage to health due to foul gases which can now escape into the living space. Therefore, ventilation of the drainage system is also a necessity.

Downpipe and Connection pipe

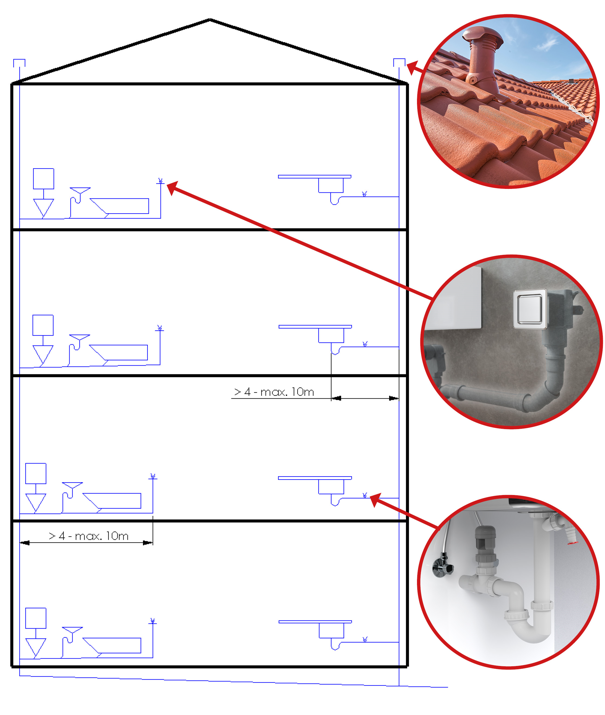

Pipe ventilation is possible at various points in the wastewater system. A basic distinction is made between main ventilation at the downpipe (through the roof) and ventilation at the connection pipes (directly at the consumers or discharge points).

Downpipe through the roof

All vertical wastewater and sewage pipes are referred to as downpipes. According to ÖNORM B 2501, every downpipe for ventilation must be run through the roof into the outside. It is important that the downpipes are laid as far as possible without deflections and with a constant diameter, as otherwise the ventilation capacities are reduced. The end of the downpipe can be designed differently depending on the type of roof. Examples of this would be functional tiles for pitched roofs or ventilation penetrations for flat roofs.

The downpipe above the roof fulfils the purpose of both ventilation for overpressure and for underpressure (aeration and de-aeration), but is essential for venting of overpressure in particular. Unlike underpressure, overpressure cannot be solved directly at the connection points, but must always be vented to the outside, otherwise sewer gases will enter the living space.

It is often argued that venting via the roof is complicated and involves additional material and labour costs, as well as heat losses that occur when penetrating the building envelope. These arguments should not be used as a reason for not installing roof ventilation, as heat losses can be prevented if the downpipe is adequately insulated. The installation of a downpipe through the roof is essential for a functioning drainage system and must not be bypassed.

There is an exception to the basic rule of running all downpipes through the roof for detached and semi-detached houses. In this case, the downpipe with the largest volume of wastewater must be designed as main ventilation (through the roof). Each additional downpipe must be equipped with an air admittance valve inside the building. This ensures safe and sufficient ventilation of these systems.

Horizontal connection pipes to the drainage points

In addition to the downpipes, horizontal connection pipes are of course also laid to the respective drainage points (e.g. floor drain, WC, washbasin, etc.). From a pipe length of 4 meters – i.e. from a distance of 4 meters between the drain point and the downpipe – a horizontal pipe must also be ‘ventilated’. As a reminder: Ventilation is necessary because otherwise the draining water creates a negative pressure that sucks out traps in the toilet or bathroom, for example, and sewer gases can then enter the living space.

There are two ways in which the ventilation of horizontal connecting pipes can be solved. The first is so-called ventilation bypass. In this case, the individual or collective connection pipe is ventilated via additional ventilation pipes that are ‘re-ventilated’ back into the downpipe on the same floor. All horizontal drain lines are thus supplied with air from the ventilated downpipe in order to avoid negative pressures in the pipe system. However, bypassing is time-consuming and involves more labour and material consumption. The simpler solution is to install an air admittance valve. There are different air admittance valves depending on the connection point, but they all follow the same basic principle: The air admittance valve is a ventilation valve that keeps the system sealed when there is positive pressure and prevents sewer gases from escaping, but opens when there is negative pressure and allows air into the pipe system.

Which air admittance valve should be installed?

An air admittance valve is therefore installed to equalise negative pressure in the piping system with atmospheric air pressure. This is to prevent traps and odour barriers from being sucked dry and odours rising from the sewer into the living space. Air admittance valves are often mistakenly seen as a problem solver. However, planning these at an early stage can prevent complaints and problems later on. As previously mentioned, the ÖNORM EN 12056-2:2000 standard prescribes ventilation of the pipe from a pipe length of 4 metres of the horizontal connecting pipe.

There are various installation scenarios for the air admittance valves

Air admittance valve for secondary downpipes in detached and semi-detached houses

- Secondary downpipes are downpipes that are not routed through the roof but are equipped with an air admittance valve.

- These secondary downpipes are often routed into the attic, where they must be fitted with a valve to prevent odour

- The HL900N air admittance valve is used here

- By using an HL900N, the downpipe can be ventilated directly next to the highest drain connection in the building

Air admittance valves for individual or collective connection pipes

- The air admittance valves directly on the horizontal connection pipes should prevent the traps at the drain points from being sucked dry and thus also prevent bad smell

- The air admittance valve should be installed at the drain point furthest away from the downpipe (see illustration)

- In wall air admittance valves (e.g. HL905N) are recommended here as they can be installed in-wall

Air admittance valves for kitchen and washbasin siphons

- In the event of problems, air admittance valves can also be retrofitted directly to the affected drain points (e.g. kitchen siphon)

- The HL904 or HL903, for example, are suitable for this. Due to their small design, these pipe aerators can easily be placed under the washbasin or kitchen sink.

Cleaning and maintenance

Ventilation valves must be installed in such a way that they can be replaced in the event of a defect without the need for structural measures. Sufficient air supply from the surrounding room must be ensured to ensure proper functioning. As long as there is no unpleasant odour from sewer gases, it can be assumed that they are functioning correctly.

Conclusion

Correct wastewater disposal in large-scale projects requires a well thought-out drainage system. Find out more about the application of ventilation techniques as well as relevant standards in our download area. There you will find practical calculation examples and basic information from the HL catalogue that will help you to successfully implement your projects and avoid undesirable side effects such as odour development or health risks. If you would like to find out more about standards, don’t hesitate to contact our sales represantatives or register for one of our seminars.